Brief introduction of extruded aquatic feed

The concept of extruding fish feed:

Puffing is a common name for extrusion. Extrusion is a processing process that integrates various processes such as mixing, shearing, heating, kneading, cooling and forming. This extruding process first decompresses the material after high temperature and high pressure treatment. A processing technique in which the instantaneous evaporation of moisture or the expansion characteristics of the material itself causes some properties of the material to change.

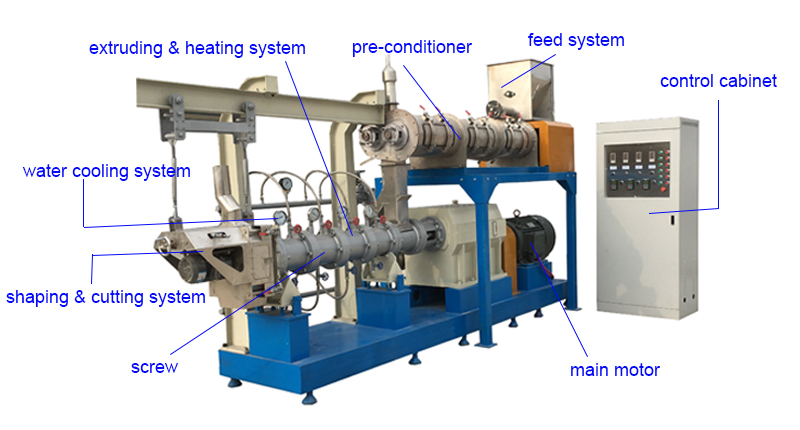

Simple process flow and puffing equipment for puffed aquatic feed production:

The general procedure for producing expanded aquatic feed is to firstly pulverize the cleaned raw materials, then mix them in a certain proportion, and then further finely pulverize them into the modulator, add steam or water to prepare for 3-5 minutes, and pre-modulate the materials to achieve preliminary ripening. Upon entering the extruder, the material changes from pellets to a viscous amorphous material under the action of heating, pressurization and mechanical shearing. The material is pushed forward by the rotation of the screw, and a certain pressure is formed behind the discharging stamper. Therefore, the material is extruded out of the machine, and the feed out of the die hole enters the atmospheric environment with low pressure, and the moisture in the high temperature material evaporates quickly and causes the material to expand, and the external rotary cutter at the end of the die will be squeezed. The processed product is cut off according to a predetermined length, and then the moisture of the feed is 9%-12% by drying, and further, the feed is packaged by grading and external coating.