Modified starch extruder making machine introduction:

Oil Drilling Modified Starch making machine can produce Denatured Starch, Pre-gelatinized starch is an effective and economical fluid loss agent in water based drilling fluids, which is a starch derivative. It is not bacterial degradation when at 120°C, environmentally acceptable and non-toxic. Modified Starch can produce a thin, slick, tough filter cake and promotes faster penetration rates with reducer friction. It can be used in all kinds of drilling fluid system. Pre-gelatinized starch is also sometimes "pregelatinized" to make them easier to dissolve during product manufacture. Modified starch is widely used in oil drilling, textile, paper and food industries.

Flow chart :

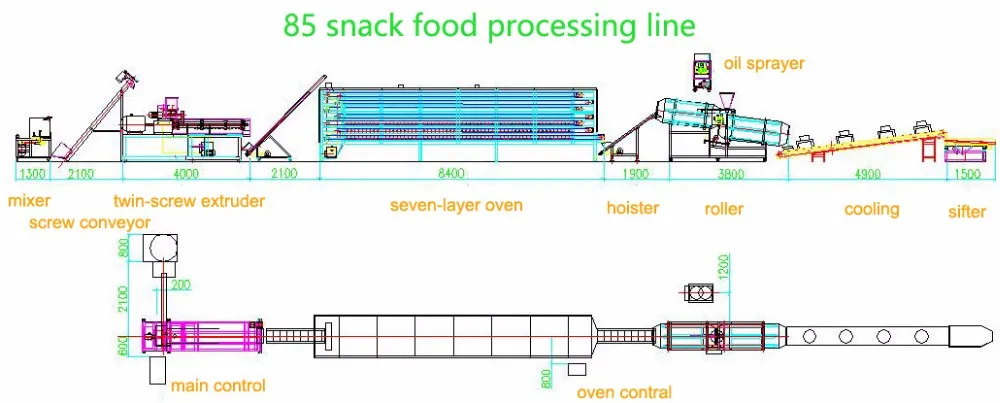

Mixer- Screw conveyor-Twin-screw extruder- Sifter-Hoister- oven -Cooling machine - Grinder-Classifying screen

Flow chart diagram:

Our engineer could design the layout drawing according to your dimension of the factory for the fish feed machines

Technical parameter

Raw material:

natural starch, like corn starch, cassava starch, tapioca starch etc

Sample of modified starch :

Equipment list in the snack food production line:

mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→Grinder→Microwave oven→cooling machine→packing machine

1)mixer of baby food processing equipment baby food production line price

2)extruder of baby food processing equipment baby food production line price

3)oven of baby food processing equipment baby food production line price

4)grinder of baby food processing equipment baby food production line price

5)Sifter of baby food processing equipment baby food production line price

6)packaging of baby food processing equipment baby food production line price